AT-Closed Vial® and Container Closure Integrity during Cryogenic Storage

More

We use cookies to offer you the best experience on our site. You can find out more about the cookies we use or disable them in the Cookie settings

Crystal L1 Robot platform enables the scaling-up strategies of biopharmaceutical companies globally. Combined with active Restricted-Access Barrier System (RABS), providing the enclosed controlled environment for aseptic filling process, this robotic filler is typically installed in Grade B.

Crystal Robot Line in RABS has a minimal footprint and is able to process up to 500 AT-Closed Vial® per hour.

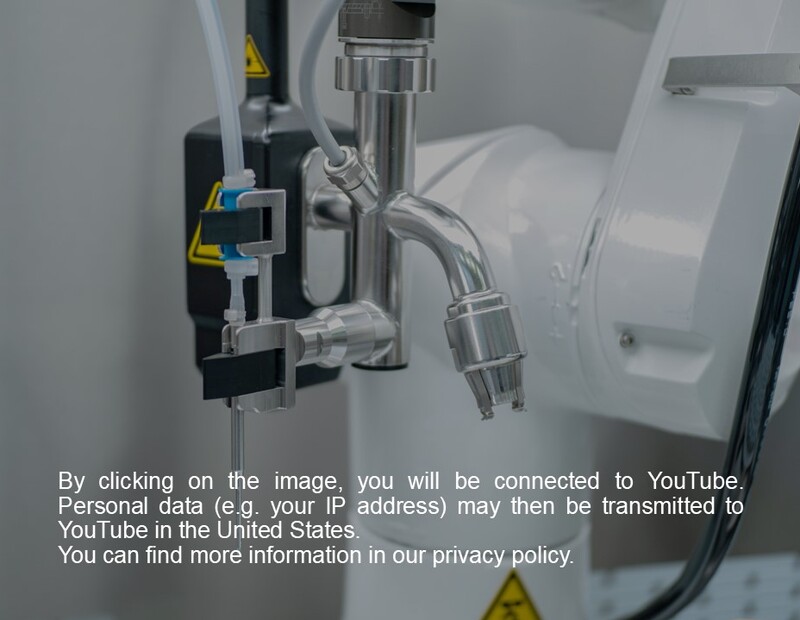

The bulk product container, remaining outside of the filling line, is connected to the operating area with the AT-Port System, the aseptic liquid connector. Through mousehole on the left side of the equipment, the nested ready-to-fill AT-Closed Vial®, and other single-use material, are introduced to the critical area, where prepared for operation.

Commanded from the Human Machine Interface (HMI), the aseptic filling line is calibrated to achieve high dosing accuracy.

The high-class cleanroom 6-axis robotic arm then begins the AT-Closed Vial® filling process, consisting of 3 steps: each AT-Closed Vial® is first filled through the stopper with a special non-coring needle, then laser re-sealed and capped by snap-fit. Each operation is performed with a dedicated tool on the robot head.

Once the AT-Nest is fully processed, the operator extracts it from the critical area via the exit mousehole.

AT-Closed Vial® and Container Closure Integrity during Cryogenic Storage

More