AT-Closed Vial® and Container Closure Integrity during Cryogenic Storage

More

We use cookies to offer you the best experience on our site. You can find out more about the cookies we use or disable them in the Cookie settings

Adoption of isolator technologies and automation is key for ensured consistency, highest sterility assurance, full GMP compliance of the aseptic fill & finish, as well as lowering its total cost of ownership.

The Cellana L1 Robot Line is an isolated fill & finish line able to process up to 500 vials per hour and can be installed in lower-class cleanroom environment, thanks to the integrated H2O2 decontamination system.

This isolated robotic aseptic fill & finish line is a result of accumulated expertise and co-engineering within the SKAN group.

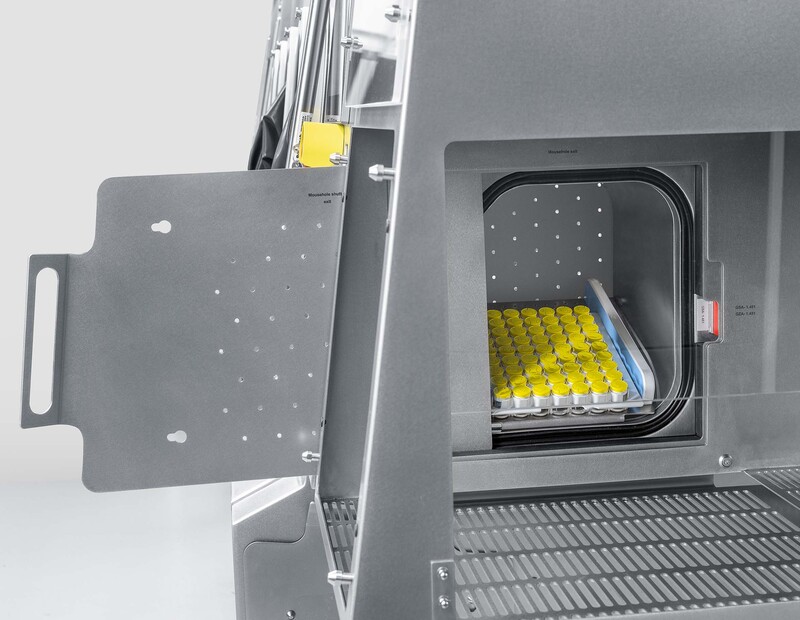

The Cellana L1 Robot Line contains the AT-Closed Vial® process within the modular isolator by SKAN. It typically consists of a Cellana isolator with integrated robotic filling equipment L1 and the rapid material airlock.

Ready-to-fill AT-Closed Vial®, organized in AT-Nest, and other consumable material are introduced through a rapid decontamination airlock, while the bulk product is aseptically connected to the main chamber of the isolator. Such configuration allows the bulk product to be homogenized and cooled.

In the H2O2 decontaminated chamber, using the glove access, the operator positions the AT-Nest, prefilled with AT-Closed Vial®, and prepares the fluid path, AT-Assembly. Activated from the HMI, the clean 6 axis robot then initiates the filling process.

With the first tool of the robot, each vial is filled through the stopper with a needle of the patented design. The use of the peristaltic pump ensures high filling accuracy and ease of guided calibration.

The robot arm then switches to the laser tool to re-seal the puncture trace on the stopper surface. Finally, the capping tool of the robot is activated to pick up a snap-fit cap from the vibrating bowl and place it on each vial in the nest.

The processed AT-Nest then is taken out of the isolator.

AT-Closed Vial® and Container Closure Integrity during Cryogenic Storage

More