AT-Closed Vial® and Container Closure Integrity during Cryogenic Storage

More

We use cookies to offer you the best experience on our site. You can find out more about the cookies we use or disable them in the Cookie settings

The Crystal M1 Filling Station is a tabletop aseptic filling system, de-risking your manual fill & finish operation.

The Crystal M1 Filling Station operates with the AT-Closed Vial®, remaining functionally closed throughout the filling process, significantly reducing the contamination risks typically associated with the manual fill & finish.

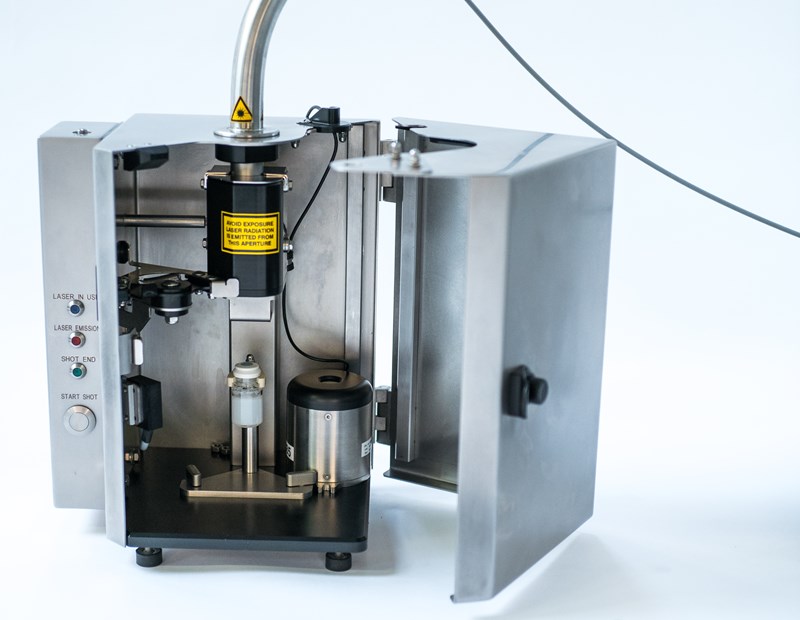

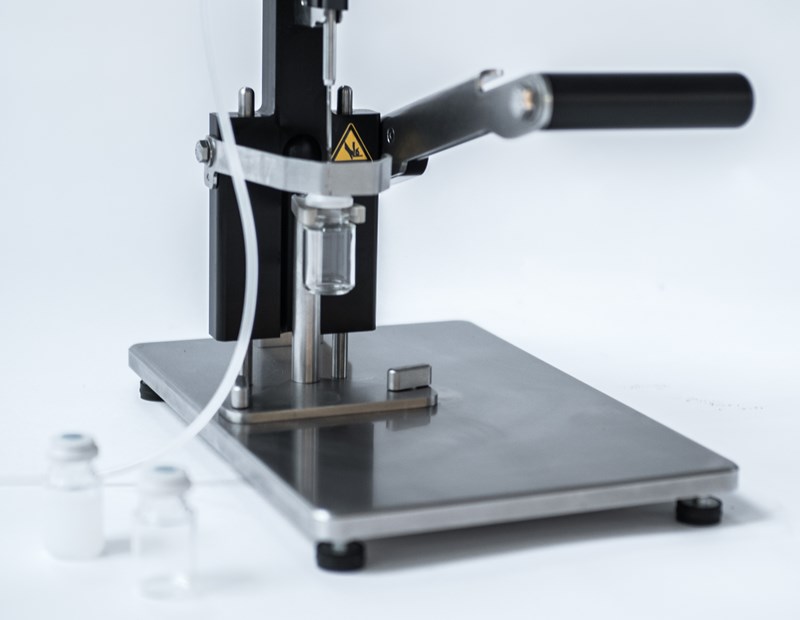

The system consists of the filling unit with its dosing system, precision balance, laser re-sealing unit and a capping tool.

Installed in a Biosafety Cabinet or an isolator, the system provides flexibility and ease of switch to the AT-Closed Vial® technology.

Using the M1 Filling Station, the AT-Closed Vial® are individually filled through the stopper, laser re-sealed and capped, while being manually transferred between the process stations within the critical area.

To prepare the batch, the bulk product is connected to the AT-Filling Kit, the dosing system and laser control unit are calibrated. For practical and ergonomic process, the AT-Closed Vial® can be provided in AT-CryoBox, accompanied with AT-Cap in rigid support.

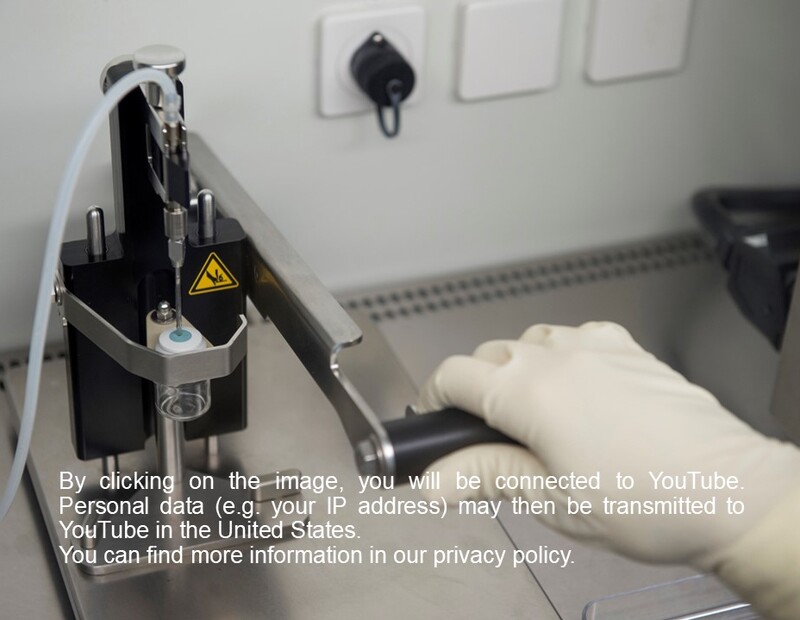

One by one, the vials are installed on the base of the filling tool. By manipulation of the lever, the piercing step with the spear-point needle is initiated. The product is safely injected in the vial, while being completely isolated from the surrounding environment.

Next, the AT-Closed Vial® is manually transferred to the laser re-sealing cabinet. Just 1 second laser shot is enough to re-close the filled vial, without any impact on the product. To complete the process, the capping tool is used to place a snap fit AT-Cap on the vial.

The AT-CryoBox with processed vials is then extracted from the critical area.

AT-Closed Vial® and Container Closure Integrity during Cryogenic Storage

More