AT-Closed Vial® and Container Closure Integrity during Cryogenic Storage

More

We use cookies to offer you the best experience on our site. You can find out more about the cookies we use or disable them in the Cookie settings

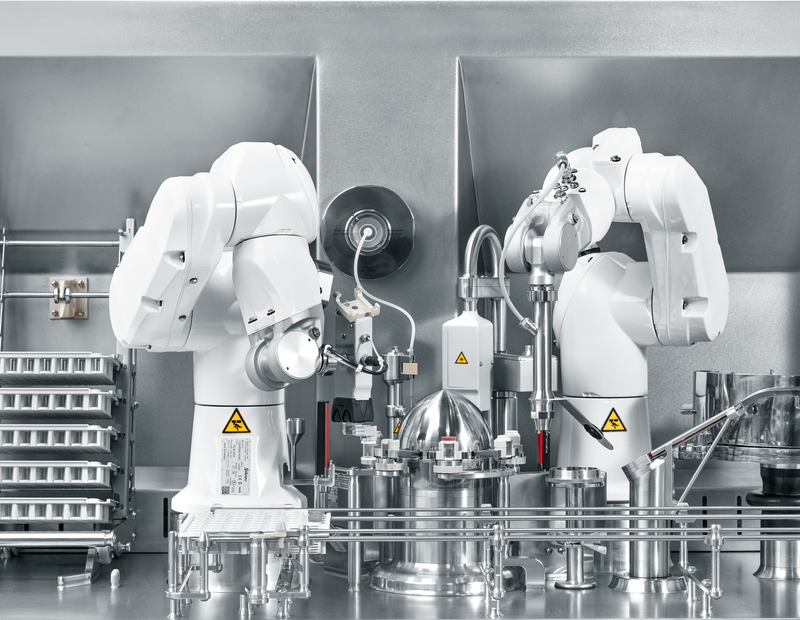

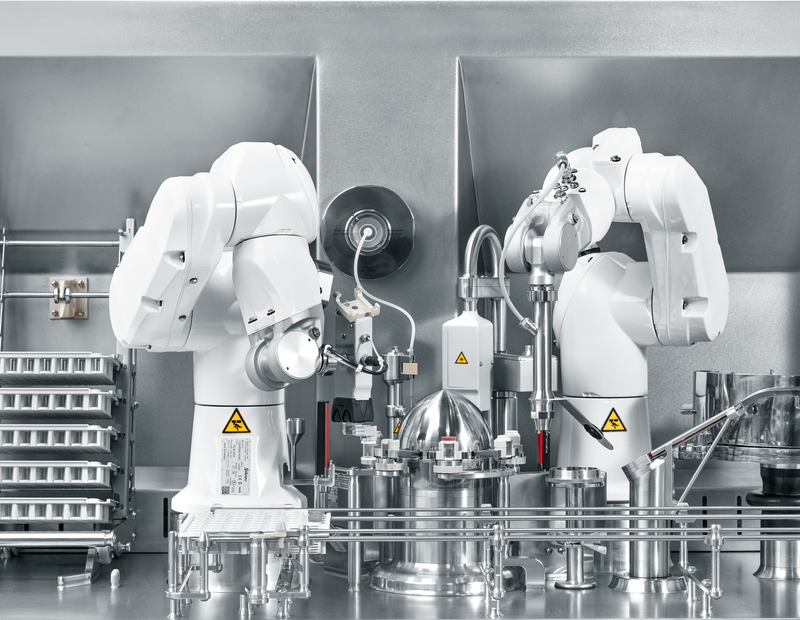

As a result of accumulated expertise and co-engineering within SKAN group, the Cellana XL1 addresses the needs of scaling-up the aseptic filling of novel pharmaceutical and biotech products, including cell and gene therapy products, their intermediate products, as viral vectors, plasmid DNA, cell banks.

The adoption of isolator technology and automation for your aseptic fill & finish process is the key for ensuring consistency, high level of sterility assurance, full GMP compliance which can lead to lower cost of ownership over time.

The Cellana XL1 is designed for versatile vial filling utilizing single-use materials to minimize change over from batch to batch. It is also compatible with other isolated modules of the Cellana to complete your manufacturing flow all in an isolator.

The ready-to-fill AT-Closed Vial®, organized in nests, and other consumable materials are introduced into the main chamber via a rapid decontamination airlock, while the bulk product is aseptically connected to the main chamber of the isolator. Such configuration allows the bulk product to be homogenized and cooled.

The robot picks up an individual vial and loads it onto the processing wheel where it will be weighed (empty), filled, laser re-sealed, weighed (filled) and capped. The processed vials are then placed back into the AT-Nest.

AT-Closed Vial® and Container Closure Integrity during Cryogenic Storage

More